HOME UNIT 1 UNIT 2 UNIT 3 UNIT 4 UNIT 5

Industrial IoT is an ecosystem of devices, sensors, applications, and associated networking equipment that work together to collect, monitor, and analyze data from industrial operations. Analysis of such data helps increase visibility and enhances troubleshooting and maintenance capabilities. It can also increase efficiencies, reduce costs, and improve safety and security.

Why should organizations consider adopting industrial IoT?

Industrial IoT enables organizations to get a wealth of actionable data from their operations. When properly aggregated and analyzed, the data helps them better control operations, with the potential to:

- Improve worker safety

- Increase production uptime by predictive maintenance of machinery

- Maintain product quality

- Help ensure regulatory compliance

- Improve operational efficiencies

- Accelerate response times with real-time collection and processing of operational data

- Manufacturing: Businesses can automate and increase the operational efficiency of their manufacturing processes.

- Oil and gas: Companies improve productivity and reduce risks by proactively identifying threats.

- Energy: Organizations use IIoT to lower costs, enhance worker and plant safety, and improve reliability.

- Agriculture: Farming businesses strive to adopt smart farming by collecting data and extracting meaningful insights to enhance productivity.

- Construction: Companies leverage the technology to collect construction-related data, improve project delivery time, and centralize site monitoring.

- Automotive: IIoT solutions aid organizations in creating safer and more efficient smart vehicles.

- Healthcare: Hospitals and clinics utilize technology to gather real-time patient health data, automate operations, and minimize human error.

The benefits of utilizing IIoT solutions are immense: from solving issues sooner and cheaper to providing better quality control and implementing green practices. Traditional industrial systems require a team of workers to track and record data, while smart machines are capable of doing this autonomously. This level of automation not only allows employees to focus on business goals but also reduces human error and makes the processes cheaper and safer.

How Does IIoT Operate?

Each IIoT system comprises interconnected devices that capture and store information, data communication infrastructures, data storage, and analytics solutions. An ecosystem of smart devices, IIoT solutions track, process, exchange, and analyze vast amounts of information to help companies distill meaningful insights. Access to real-time data offers employees and executives the most accurate and up-to-date information to make data-driven decisions. For example, in manufacturing, IIoT applications include barcode scanners, web cameras, signal lights, and sensors that measure temperature, humidity, and vibration. In other words, it’s a collaboration of systems, machines, and people empowering each other to deliver continuous business growth.

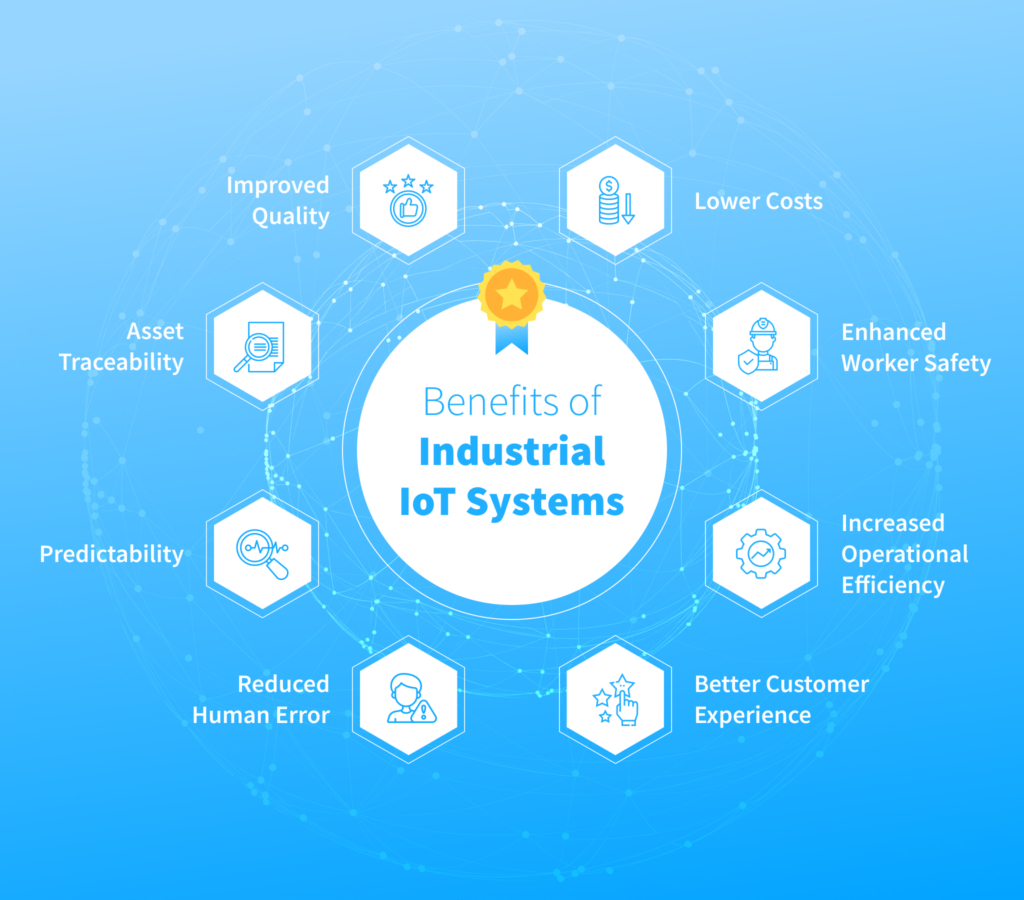

Benefits of Industrial IoT Systems

IoT systems offer access to an unprecedented amount of information. By tracking each piece of equipment, companies can leverage crucial findings to make their operations more efficient, transparent, and safe. In this part, we will cover the most significant advantages of employing IIoT solutions in your business.

Reduced Human Error

Data collection automation relieves employees from performing manual activities associated with capturing and storing information. Paper-based methods of data gathering are bound to lead to human mistakes and inconsistencies. On top of that, it’s highly difficult to enforce a unified format when dealing with manual labor. Automated real-time data collection increases overall accuracy and generates valuable insights.

Predictability

The ability to forecast when a certain piece of equipment might experience issues is useful for businesses across industries. Utilizing data analytics, companies can plan necessary maintenance and repair to avoid larger bills. Especially on a production line, the cost of machine failure can be devastating and lead to downtime and associated expenses. Dealing with maintenance issues proactively improves predictability and transparency.

Asset Traceability

Asset management can become increasingly complex when the company grows and introduces new products. Tracing each item down the supply chain pipeline is highly difficult with a certain level of automation. Industrial IoT applications can monitor the location, status, and condition of goods and send out alerts in case some item is jeopardized. If something goes wrong during delivery, you can immediately salvage the situation to avoid customer complaints and additional expenses.

Improved Quality

Automation eliminates errors and oversights that can be missed by a human. Furthermore, through industrial IoT applications, organizations can adopt best practices and unlock additional insights that can make the business more efficient. As a result, your production suffers from fewer defects and drops in quality.

Lower Costs

Increased productivity, lack of product defects, and predictive maintenance are benefits that will also reduce manufacturing costs. Knowing real-time data regarding machine health and asset management also aid in predictability. Having a predictable business can be extremely lucrative and eliminate unnecessary concerns, actions, and expenses.

Enhanced Worker Safety

The safety and well-being of employees make a huge difference in the company’s operations. Investing in modern equipment enables organizations to safeguard factories, plants, and warehouses to minimize potential workplace accidents. IIoT sensors within the workplace provide real-time data regarding air quality, toxic gas leaks, and other environmental aspects. You can also place sensors on employees to monitor their vitals and prevent them from overworking and developing health issues.

Increased Operational Efficiency

Having access to time-sensitive data aids companies in improving their operational efficiency. By automating workflows, delivering high-quality products, and investing in predictability, businesses can establish higher productivity across the organization. Creating a physically and mentally safe work environment for your employees also aids in boosting the overall effectiveness of the processes.

Better Customer Experience

Finally, your customers will also gain from IIoT adoption. While enhanced quality control ensures the best products reach the shelves, they will also benefit from optimized delivery times. Furthermore, IIoT systems help managers identify potential ways to improve customer experience by analyzing user data.

The role of IT in industrial IoT

IIoT malfunctions can have a major impact on operations, ranging from production downtime to compromising worker safety or damaging the environment. IIoT installations benefit from rigorous IT processes, tools, and best practices. IT can scale and secure IIoT deployments to help ensure success.

A reliable network:

Organizations rely more and more on the quantity and quality of data they get from their operations. IT must strive to ensure that a reliable network with sufficient bandwidth capacity is in place so time-sensitive data can be transmitted without delay to applications in data centers or the cloud.

The network that connects IIoT devices and sensors needs to support diverse physical channels. For example, although Ethernet cables may connect devices commonly found on the factory floor, wireless technologies such as 5G, 4G LTE, NFC, RFID, Bluetooth, NB-IOT, LoRaWAN, and Wi-SUN may also be required for connectivity.

Comments

Post a Comment