HOME UNIT 1 UNIT 2 UNIT 3 UNIT 4 UNIT 5

SCADA

SCADA (supervisory control and data acquisition) is a category of software applications for controlling industrial processes, which is the gathering of data in Real Time from remote locations in order to control equipment and conditions. SCADA provides organizations with the tools needed to make and deploy data-driven decisions regarding their industrial processes.

One of the most commonly used types of industrial control system, SCADA can be used to manage almost any type of industrial process.

SCADA systems include hardware and software components. The hardware gathers and feeds data into field controller systems, which forward the data to other systems that process and present it to a human-machine interface (HMI) in a timely manner. SCADA systems also record and log all events for reporting process status and issues. SCADA applications warn when conditions become hazardous by sounding alarms.

Components of a SCADA system

SCADA systems include components deployed in the field to gather real-time data, as well as related systems to enable data collection and enhance Industrial automation. SCADA components include the following:

- Sensors and actuators. A sensor is a feature of a device or system that detects inputs from industrial processes. An actuator is a feature of the device or system that controls the mechanism of the process. In simple terms, a sensor functions like a gauge or meter, which displays the status of a machine; an actuator acts like a switch, dial or control valve that can be used to control a device. Both sensors and actuators are controlled and monitored by SCADA field controllers.

- SCADA field controllers. These interface directly with sensors and actuators. There are two categories of field controllers:

- Remote telemetry units, also called remote terminal units (RTUs), interface with sensors to collect telemetry data and forward it to a primary system for further action.

- Programmable logic controllers (PLCs) interface with actuators to control industrial processes, usually based on current telemetry collected by RTUs and the standards set for the processes.

- SCADA supervisory computers. These control all SCADA processes and are used to gather data from field devices and to send commands to those devices to control industrial processes.

- HMI software. This provides a system that consolidates and presents data from SCADA field devices and enables operators to understand and, if needed, modify the status of SCADA-controlled processes.

- Communication infrastructure. This enables SCADA supervisory systems to communicate with field devices and field controllers. This infrastructure enables SCADA systems to collect data from field devices and to control those devices.

Features of SCADA systems

Although SCADA systems may include special features for specific industries or applications, most systems support the following features:

- Data acquisition is a foundation of SCADA systems; sensors collect data and deliver it to field controllers, which, in turn, feed data to the SCADA computers.

- Remote control is achieved through the control of field actuators, based on the data acquired from field sensors.

- Networked data communication enables all SCADA functions. Data collected from sensors must be transmitted to SCADA field controllers, which, in turn, communicate with the SCADA supervisory computers; remote control commands are transmitted back to actuators from the SCADA supervisory computers.

- Data presentation is achieved through HMIs, which represent current and historical data to the operators running the SCADA system.

- Real-time and historical data are both important parts of the SCADA system, as they enable users to track current performance against historical trends.

- Alarms alert SCADA operators to potentially significant conditions in the system. Alerts can be configured to notify operators when processes are blocked, when systems are failing, or when other aspects of SCADA processes need to be stopped, started or adjusted.

- Reporting on SCADA system operations can include reports on system status, process performance and reports customized to specific uses.

SCADA architecture

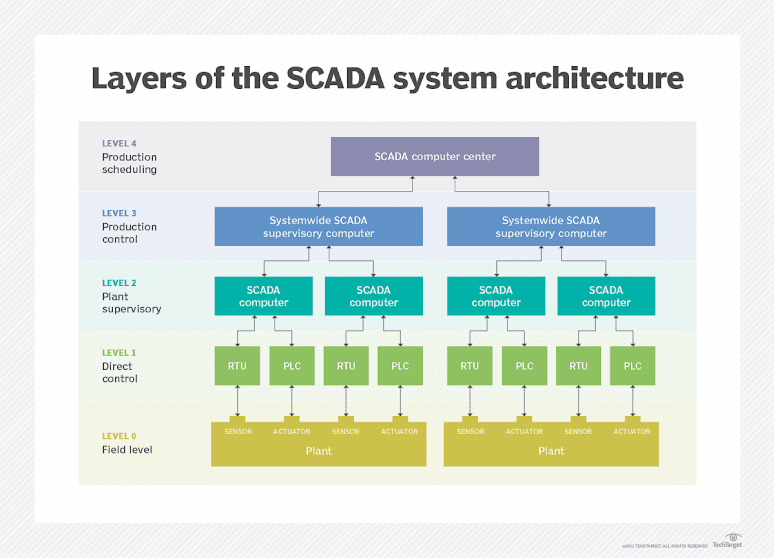

SCADA systems operate at five of the six levels defined in the Purdue Enterprise Reference Architecture for enterprise integration:

- Level 0. The field level includes field devices, such as sensors, used to forward data relating to field processes and actuators used to control processes.

- Level 1. The direct control level includes local controllers, such as PLCs and RTUs, that interface directly with field devices, including accepting data inputs from sensors and sending commands to field device actuators.

- Level 2. The plant supervisory level includes local supervisory systems that aggregate data from level controllers and issue commands for those controllers to carry out.

- Level 3. The production control level includes systemwide supervisory systems that aggregate data from Level 2 systems to produce ongoing reporting to the production scheduling level, as well as other site or regionwide functions, like alerts and reporting.

- Level 4. The production scheduling level includes business systems used to manage ongoing processes.

SCADA use cases and industry examples

SCADA is used to assist in automating and managing industrial processes that have become too complex or cumbersome for human monitoring and control. SCADA is particularly useful for processes that can be monitored and controlled remotely, especially in cases where it is possible to reduce waste and improve efficiency.

Some common industry examples of SCADA industrial automation are the following:

- electricity generation and distribution;

- oil and gas refining operations;

- telecommunications infrastructure;

- transportation and shipping infrastructure;

- fabrication and other industrial processing;

- food and beverage processing;

- chemical manufacturing; and

- utilities infrastructure, including water and waste control.

Comments

Post a Comment